Search

Search

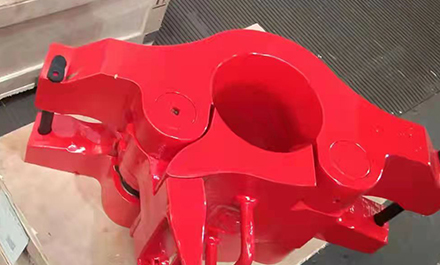

Drill Pipe Elevator

Nov 15 ,2023 | Hits:370

1. It is manufactured according to API 8C and 7K standards and has a national production license.

2. Made using high-quality alloy steel hot stamping process.

3. Is the strength test conducted using finite analysis method?

ABAQUS components, electrical logging method, and force testing.

4. Heat treatment adopts the new term of dual liquid quenching.

5. Each product must undergo testing and flaw detection before leaving the factory.

|

Type

|

Rated Load (KN/US ton)

|

Drill Pipe Size |

Elevator Upper/Lower Opening Diameter (mm)

|

Net Weight

|

|

|

In |

мм |

||||

|

CD2 7/8EU-150 |

1335/150 |

2 7/8EU |

73.0 |

86/76 |

73 |

|

CD3 1/2ED-150 |

|

3 1/2EU |

88.9 |

103/92 |

76 |

|

CD3 1/2EU-250 |

2225/250 |

3 1/2EU |

88.9 |

103/92 |

96 |

|

CD4IU-150 |

1335/150 |

4IU |

101.6 |

110/105 |

85 |

|

(CD4EU-150) |

|

4EU |

101.6 |

122/118 |

95 |

|

(CD4EU-250) |

2225/250 |

4EU |

101.6 |

122/118 |

125 |

|

CD4 1/2EU-150 |

1335/150 |

4 1/2EU |

114.3 |

131/118 |

92 |

|

(CD4 1/2EU-250) |

2225/250 |

4 1/2EU |

14.3 |

(131/118) |

130 |

|

|

|

5IEU |

127 |

135/131 |

|

|

Note: Parenthesized types are available for selection |

|||||